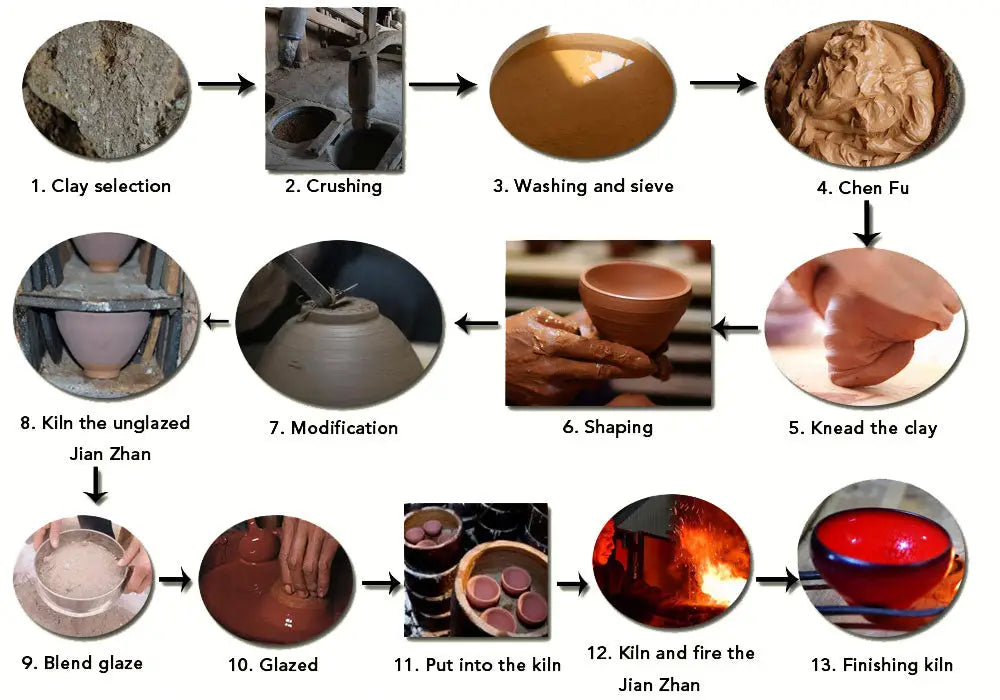

🔥 The Art of Making Jian Zhan

Creating a Jian Zhan is a process that blends ancient technique with extreme patience and precision. Each step preserves centuries of craftsmanship, and every cup carries a story of earth, fire, and mastery.

1. Clay Selection

The unique black glaze of Jian Zhan requires clay and glaze with a high iron content. While many kilns during the Song Dynasty tried to replicate this effect, only the clay from Jianyang had the right mineral composition to succeed.

2. Crushing & Sifting

Both the clay and glaze are pulverized to a fine texture. They are then sieved to ensure the right consistency — neither too thick nor too thin. Clay is sent to a slurry tank; glaze goes to its own pool.

3. Aging the Clay (Chen Fu)

The clay is stored in a controlled environment — away from sunlight and airflow, with ideal humidity and temperature — for a period of rest. This makes the clay more stable and workable.

4. Kneading

The clay is kneaded to remove air bubbles and impurities, ensuring uniform density and moisture. This step also helps prevent cracking during later stages.

5. Shaping

The vessel is shaped by hand or with a wheel. Jian Zhan bowls typically feature a shallow foot ring and wide mouth for optimal tea appreciation.

6. Trimming & Refining

After shaping, the foot and inner ring are refined with a knife to smooth and perfect the silhouette — a small but important detail in Jian Zhan aesthetics.

7. Bisque Firing

Before glazing, the raw piece is fired once at a lower temperature. This strengthens the clay and helps identify and remove any pieces prone to cracking.

8. Glaze Preparation

The traditional Jian Zhan glaze is made from natural iron ore and plant ash — simple ingredients that, under fire, give birth to complex crystalline patterns that are unique to each cup.

9. Glazing

Jian Zhan is typically half-glazed, with a carefully controlled glaze line. The glaze thickness must be just right:

– Too thin → no room for crystal growth

– Too thick → may stick to kiln base

10. Kiln Loading

Each piece is placed carefully into the kiln with a base layer of alumina powder to prevent sticking.

11. Firing

The firing process is the most critical and mystical part of Jian Zhan making. The temperature, reduction time, and oxygen control must be meticulously handled. The craftsman often remains near the kiln throughout, watching the fire and listening to the clay.

12. Final Inspection

Not every piece survives. Many will crack or develop flaws. Only a few — those that reveal the right color, form, and crystal texture — pass inspection and are selected for tea masters and collectors around the world.

🏮 Every Jian Zhan is One of a Kind

Because of the unpredictable alchemy between fire, glaze, and time, no two Jian Zhan cups are ever the same. Each one carries the fingerprint of the flame — a reflection of ancient wisdom, and a gift to your tea journey.

Ready to Choose Your First Tenmoku Jian Zhan?

Explore our handpicked collection of iron-glazed Jian Zhan teaware and begin your mindful tea journey today.

Browse Tenmoku Jian Zhan →