Dehua White Porcelain: A Tradition of Pure Craft and Beauty

Dehua White Porcelain: A Tradition of Pure Craft and Beauty

In the misty mountains of Fujian province lies Dehua, a region celebrated for one of China’s finest ceramics traditions. Dehua white porcelain — known in the West as “Blanc de Chine” — has been produced since the Ming Dynasty and revered worldwide for its pure milky hue and elegant forms. Over the centuries, this “white gold” of Chinese porcelain has earned legendary status in the ceramics world, standing alongside Jingdezhen’s blue-and-white ware as a pinnacle of Chinese craftsmanship.

What makes Dehua porcelain truly special is its 温润如玉 (“warm and lustrous like jade”) white glaze and the exquisite sculptural artistry it inspires. The local clay’s unique chemistry — naturally low in iron — fires to a translucent ivory-white tone that distinguishes Dehua wares from all others. Artisans often carve intricate designs or shape graceful forms, from delicate teaware to serene Guanyin figurines, that come alive under the smooth glaze. The result is porcelain that feels soft yet radiant, with details that capture a timeless, tranquil beauty.

For tea connoisseurs and art lovers alike, Dehua porcelain represents more than just ceramics — it’s a living heritage. At Tealibere, we cherish this legacy and are committed to bringing the handmade beauty of Dehua’s Chinese white ceramics to the world. Each piece of teaware from Dehua in our collection is crafted in the time-honored way, carrying with it a story steeped in tradition. Join us as we journey through that story: the traditional craft process that turns raw clay into a porcelain treasure.

1. Selecting Clay (选泥)

Every masterpiece begins with the earth. Dehua artisans start by hand-selecting fine porcelain clay from local quarries. This clay — rich in kaolin and remarkably pure — determines the porcelain’s quality and color. Workers wash and refine the raw clay to remove impurities, then knead it thoroughly to achieve a smooth, pliable consistency. By ensuring the clay is pristine and well-prepared, the foundation is set for creating porcelain that will fire to a flawless white.

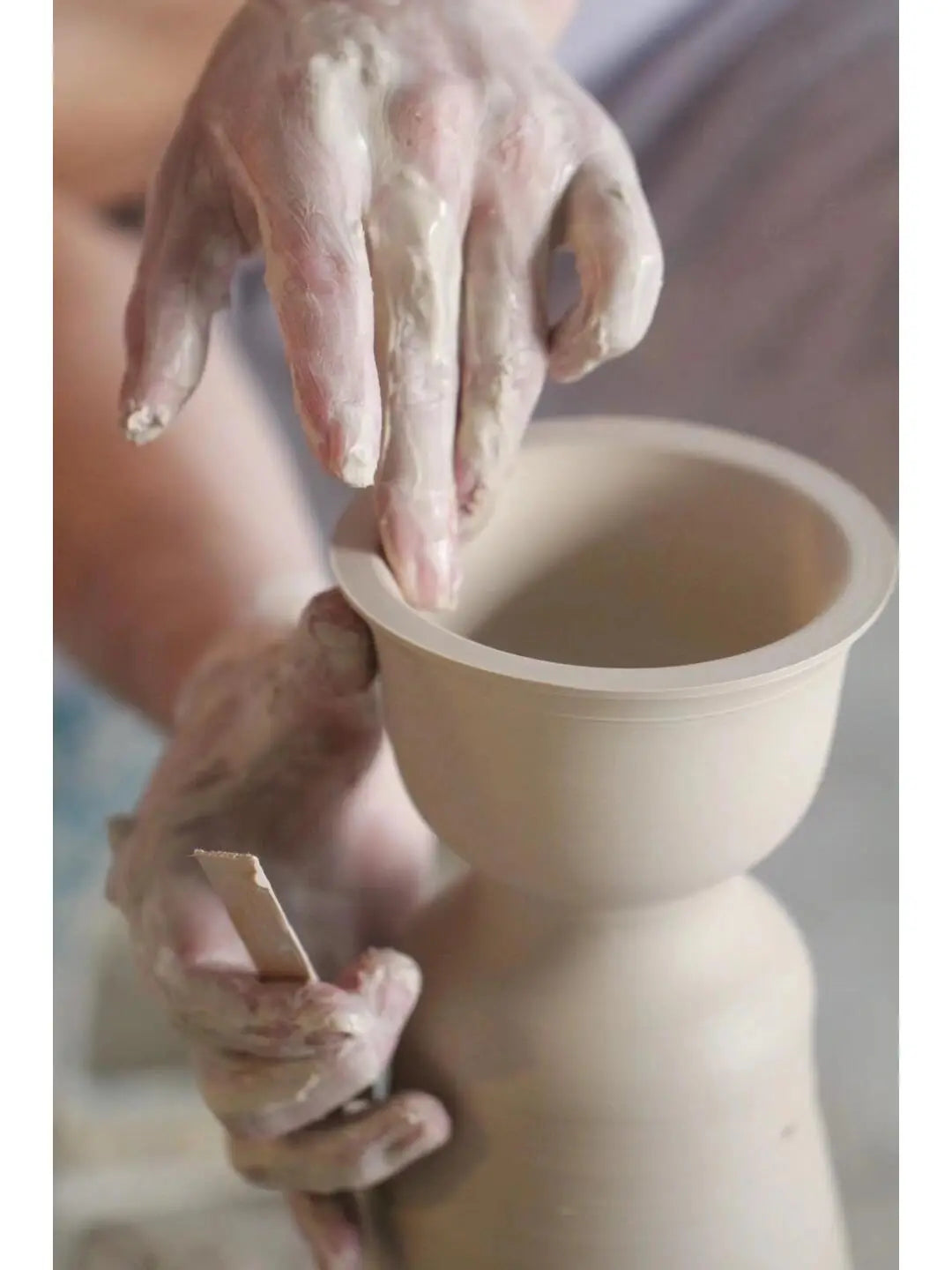

2. Throwing on the Wheel (拉坯)

Next comes shaping the clay on the potter’s wheel. The artisan centers a lump of soft clay on the wheel and, with steady hands, coaxes it upward and outward into the desired form. This process, called 拉坯 (wheel throwing), requires practiced skill and concentration. In a matter of minutes, a shapeless mound of clay begins to resemble a teacup, bowl, or teapot body. The craftsman keeps the emerging vessel symmetric and the walls of even thickness — an essential foundation for a well-balanced piece of teaware.

3. Trimming the Shape (修坯)

After the piece dries to a leather-hard firmness, it undergoes 修坯 — the careful refinement of its form. The artisan places the semi-dried piece on the wheel again (now as a trimming wheel) and uses sharp tools to shave away excess clay, smooth the surfaces, and perfect the curves. The foot of the vessel is neatly pared and any unintended thickness is trimmed down. This step demands patience and a keen eye: a well-trimmed piece not only looks more elegant, but also fires more evenly, reducing the risk of warping or cracks.

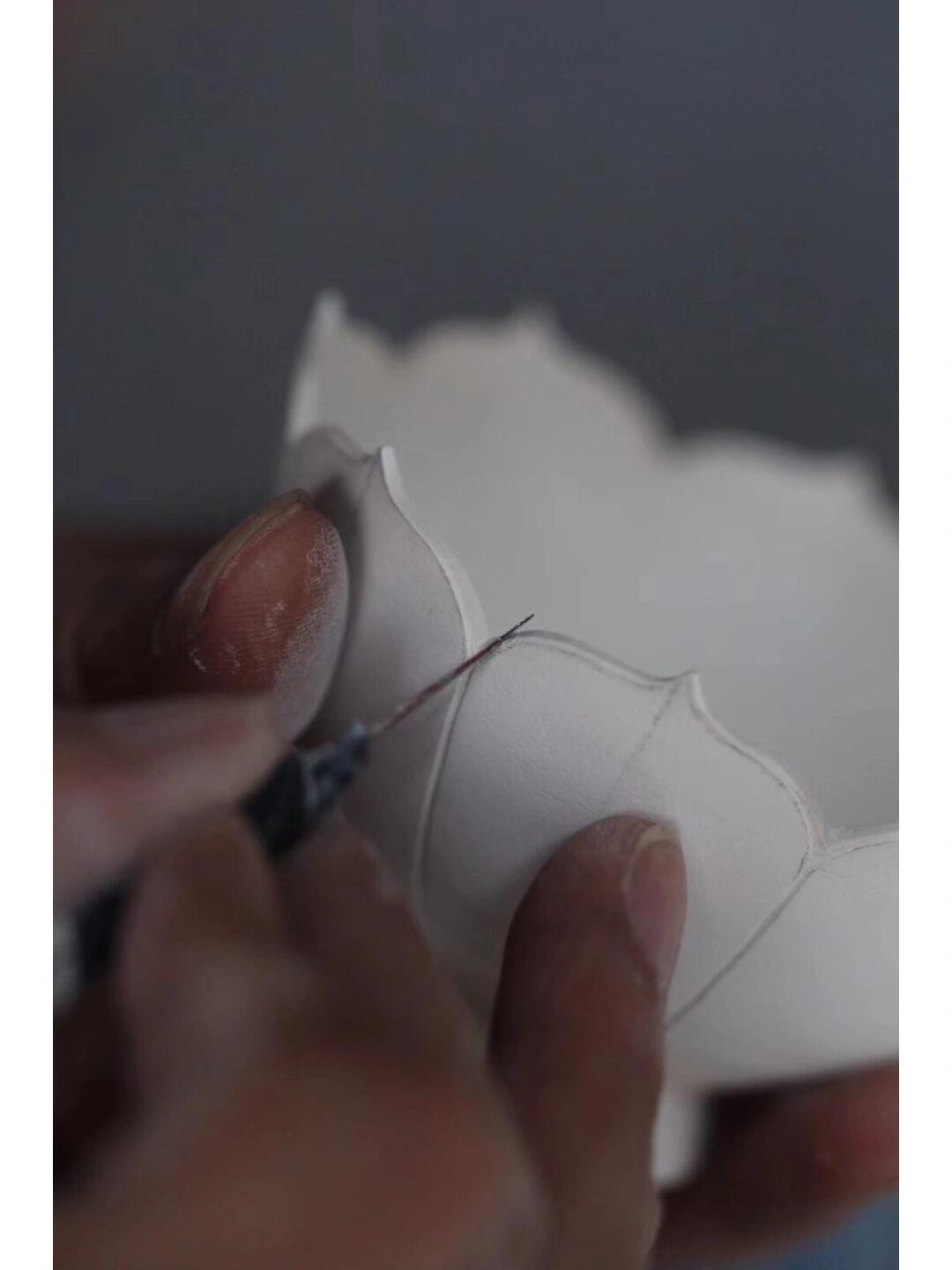

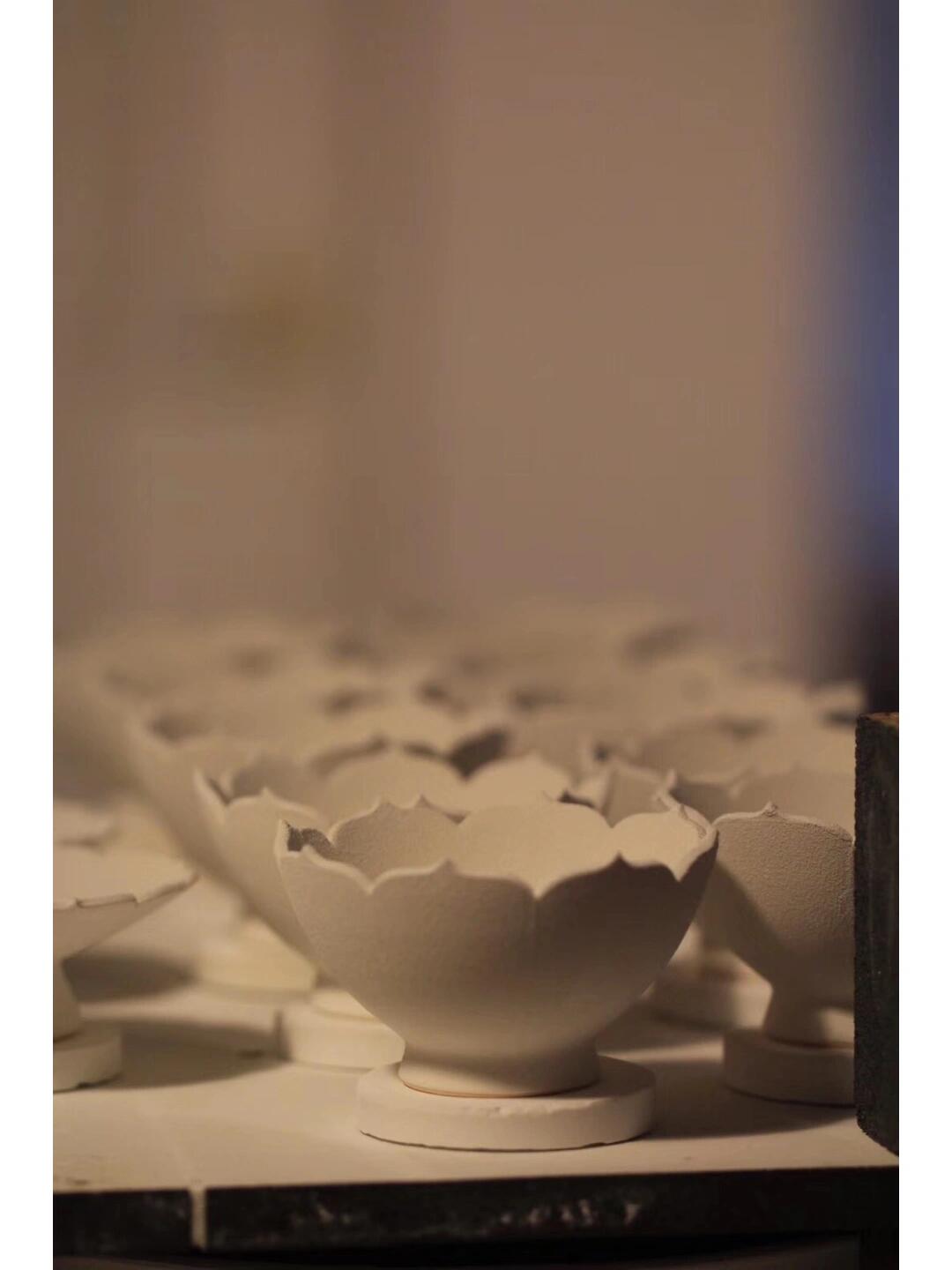

4. Carving Details (雕刻)

With the form refined, some pieces receive further artistry through hand carving. Using small knives and carving tools, the artist incises patterns or sculpts details onto the surface of the semi-hardened clay. This could range from subtle textures on a teapot’s body to elaborate motifs of flowers or dragons on a decorative vase. Dehua’s porcelain clay is superbly suited for fine carving — its smooth, firm texture allows extremely delicate lines and relief. The 雕刻 (carving) stage breathes life into the piece, infusing it with personal artistry and cultural symbolism that will endure beneath the glaze.

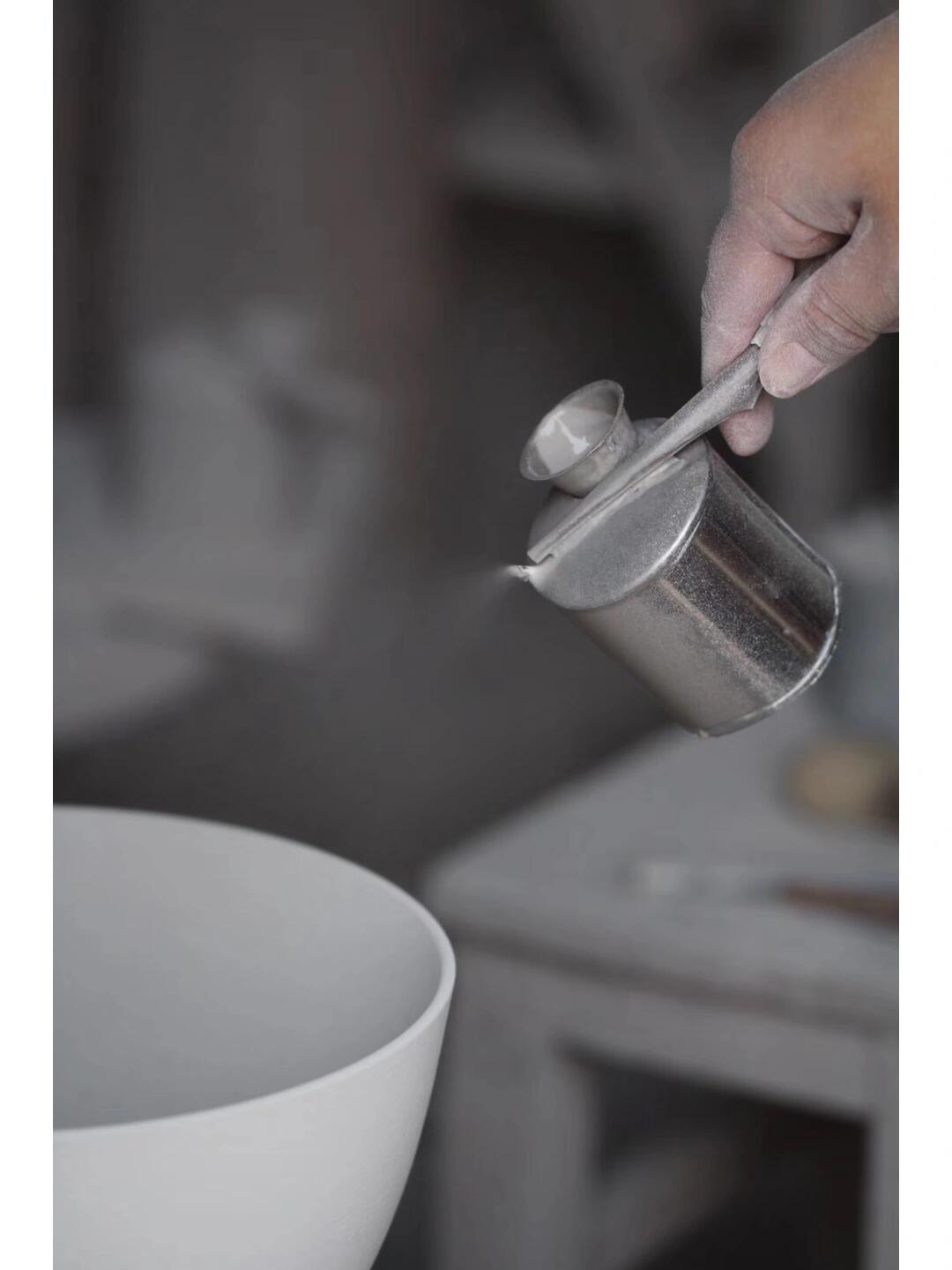

5. Glazing the Biscuit (施釉)

Once the unfired piece (now a dry “biscuit” clay form) is fully dried and cleaned, it’s time to apply the glaze. The artisan prepares a traditional clear glaze mixture and either dips the piece into it or carefully brushes it on. This step, known as 施釉 (glazing), requires a steady hand to ensure an even, flawless coat. For Dehua white porcelain, the glaze is formulated to enhance the clay’s natural whiteness — after firing it will turn into a glassy, translucent layer often described as 猪油白 (“pig’s fat white”) for its rich, creamy sheen. A perfectly glazed piece will emerge from the kiln with a smooth, lustrous surface that accentuates every carved detail beneath.

6. Loading the Kiln (装窑)

When the glazed pieces are ready, they are carefully stacked into the kiln for firing. In traditional Dehua workshops, this involves placing each piece in a protective clay sagger or on a kiln shelf, and arranging them so that no item touches another. This process, called 装窑 (loading the kiln), is meticulous work: the artisans must maximize kiln space while leaving enough airflow between pieces for even heating. Whether using an old-style wood-fired dragon kiln or a modern electric furnace, the goal is the same — to load the kiln evenly and safely before sealing it for the intense firing ahead. At this stage, days (or weeks) of careful crafting are assembled in one chamber, poised for their transformation by fire.

7. Firing in the Kiln (烧制)

Firing is the critical climax of porcelain making. Over many hours, the kiln is heated to around 1300°C (2370°F) to vitrify the clay and melt the glaze. Inside, the pieces glow orange-hot as the 烧制 (firing) process transforms them at the molecular level — the clay body fuses into true porcelain and the glaze turns into a glassy coat. Controlling the firing is an art in itself: the temperature must reach the right peak and then cool slowly to avoid stress in the wares. In the past, Dehua kiln masters judged heat by flame color and intuition; today’s electric kilns add precision, but the suspense remains. The intense heat brings out the porcelain’s strength and its delicate white sheen. When the firing is complete and the kiln is finally opened, the once-earthy creations have become porcelain, ringing with a bright, translucent beauty.

8. Unloading and Inspection (出窑)

After the kiln cools down (often taking a day or more), it’s time to open it and reveal the results. The moment of 出窑 (unloading the kiln) is both exciting and nerve-wracking. Artisans carefully remove each piece, often using long tongs or protective gloves, and line them up for inspection. In daylight, the porcelain is examined: the glaze should be smooth and lustrous, the color a warm ivory white, and every carved detail preserved. A successful firing means the vast majority of pieces emerge perfect; a few may show cracks or blemishes and are set aside. For the perfected pieces, this is a moment of triumph — the vision of the artist has survived the flames. Each finished Dehua porcelain cup, teapot, or statue now carries the story of its creation, ready to be held in the hands of tea lovers and connoisseurs, bridging the past and present with every sip.

Choose Your First Dehua Porcelain Piece

Explore the serene beauty of Dehua Blanc de Chine for yourself — each piece carries the spirit of an age-old craft into your tea ritual.

Browse Dehua Porcelain →