The Art of Jingdezhen Enamel Porcelain

Jingdezhen, known as the porcelain capital of China, is world-renowned for its exquisite enamel porcelain. The craftsmanship has been passed down through generations, blending intricate artistry with centuries-old tradition. Creating a masterpiece involves not just artistic skill, but also patience, precision, and the spiritual dedication of the artisans.

1. Clay Shaping (拉坯)

The artisan begins by shaping the porcelain using a potter's wheel, forming the basic vessel with soft kaolin clay.

2. Trimming (利坯)

Once partially dried, the shaped body is refined by trimming and smoothing to achieve the perfect form.

3. First Firing (第一次烧制)

The unglazed porcelain is fired in the kiln to strengthen the body, preparing it for the next steps.

4. Glazing (上釉)

The vessel is dipped or brushed with a base glaze that gives the porcelain its signature shine and translucency.

5. Second Firing to Form Porcelain (第二次烧制成瓷)

The glazed piece is fired again at high temperatures to transform it into finished white porcelain.

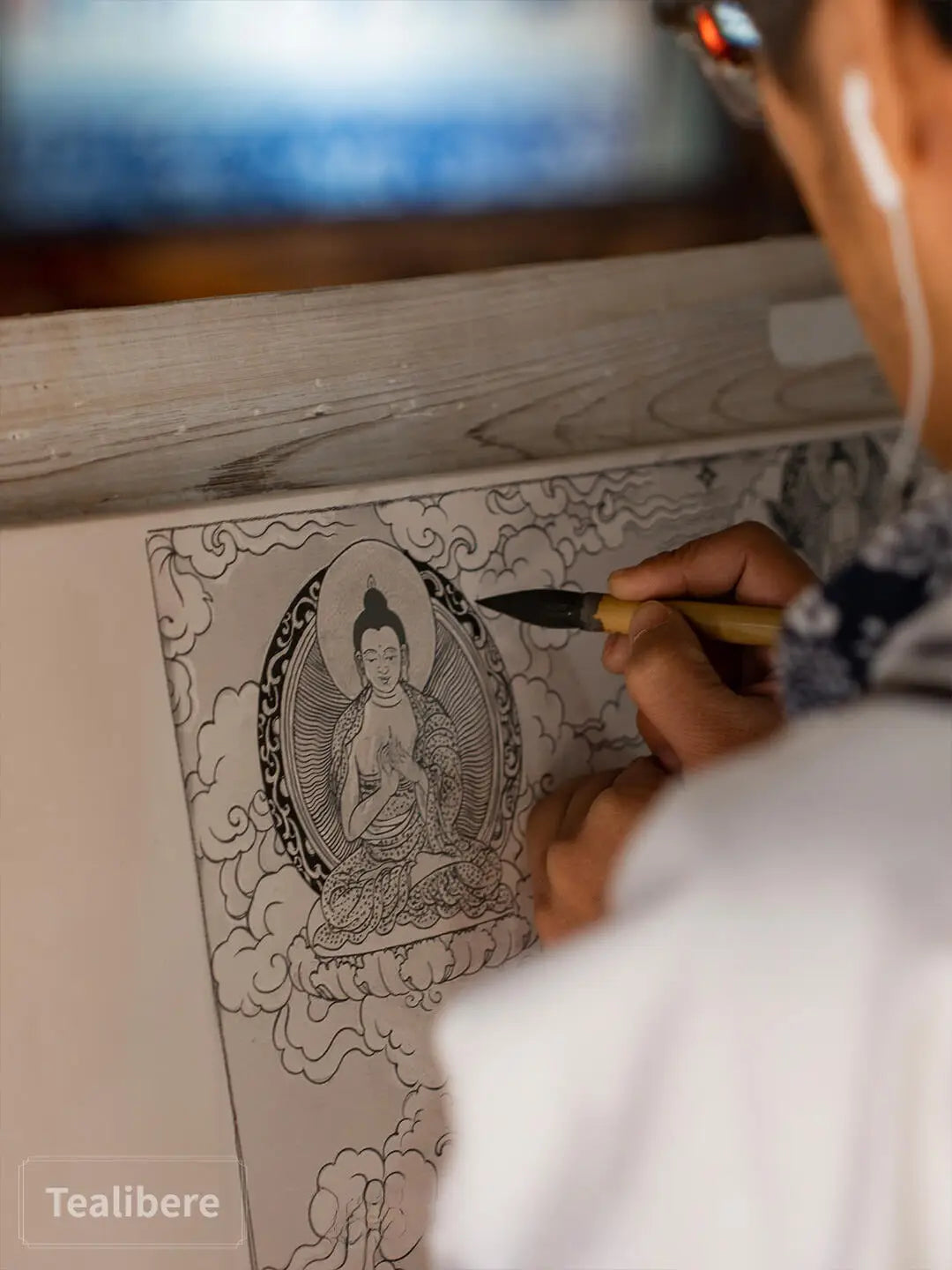

6. Hand-Painting (手绘图案)

Skilled painters illustrate intricate traditional patterns and motifs using fine brushes and mineral pigments.

7. Filling with Opaque White Enamel (填玻璃白)

A traditional step where artisans fill selected areas with glassy white enamel to enhance contrast and layering.

8. Third Firing to Seal Enamels (第三次烧制烧合)

The painted porcelain undergoes a lower-temperature firing to fuse the enamel decoration onto the surface.

9. Hand Coloring (手工填色)

Additional colors and gold accents are filled in by hand, adding richness and depth to the final piece.

10. Signature & Stamping (落款)

The artist’s mark and seal are added, often with a brush or stamp, to authenticate the creation.

11. Final Firing (第四次烧制成品)

A final firing solidifies all decorations and finishes the piece into its final, gleaming state.

Ready to Choose Your First Jingdezhen Porcelain?

Explore the timeless beauty of Jingdezhen enamel porcelain — where centuries-old craftsmanship meets vivid hand-painted detail.

Browse Jingdezhen Porcelain →Gallery: Jingdezhen Porcelain in Detail